Committed to quality and food safety

Over the last five decades Royal Canin have put nutritional quality and product safety at the heart of our operations worldwide. This attention to the very smallest details helps us deliver the most precise and effective health nutrition for pets.

Royal Canin Pet Food

All products of Royal Canin are developed by the world-leading team of dietitian nutritionists at the headquarters in France. No matter where the products are manufactured, the quality and characteristic of the product conforms to our global standards. Product development includes long-term observations on cats and dogs raised by the pet centers located in Aimargues, France and Lewisburg, State of Ohio, U.S.A., together with the study on the uniqueness of different cat and dog breeds.

Optimal nutritional balance to protect pet’shealth

The nutritional demand of cats and dogs varies according to breed, age, body type and lifestyle. Royal Canin has developed pet foods suitable for different types of cat and dog by integrating more than 40 kinds of nutrients in accordance with the principle of nutritional balance. Moreover, pet foods that can satisfy special needs are also developed: cats and dogs with certain diseases or at older ages, for instance.

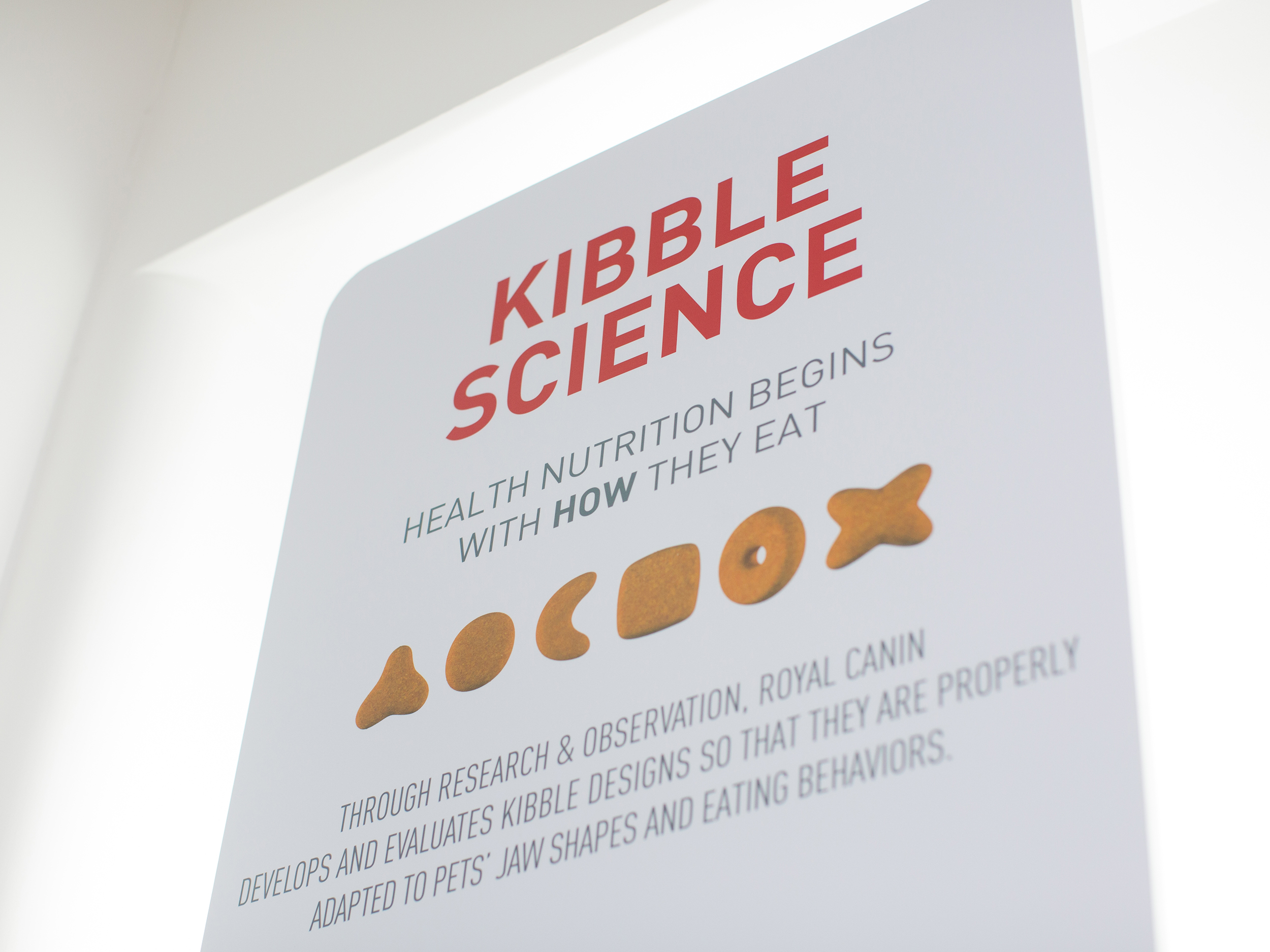

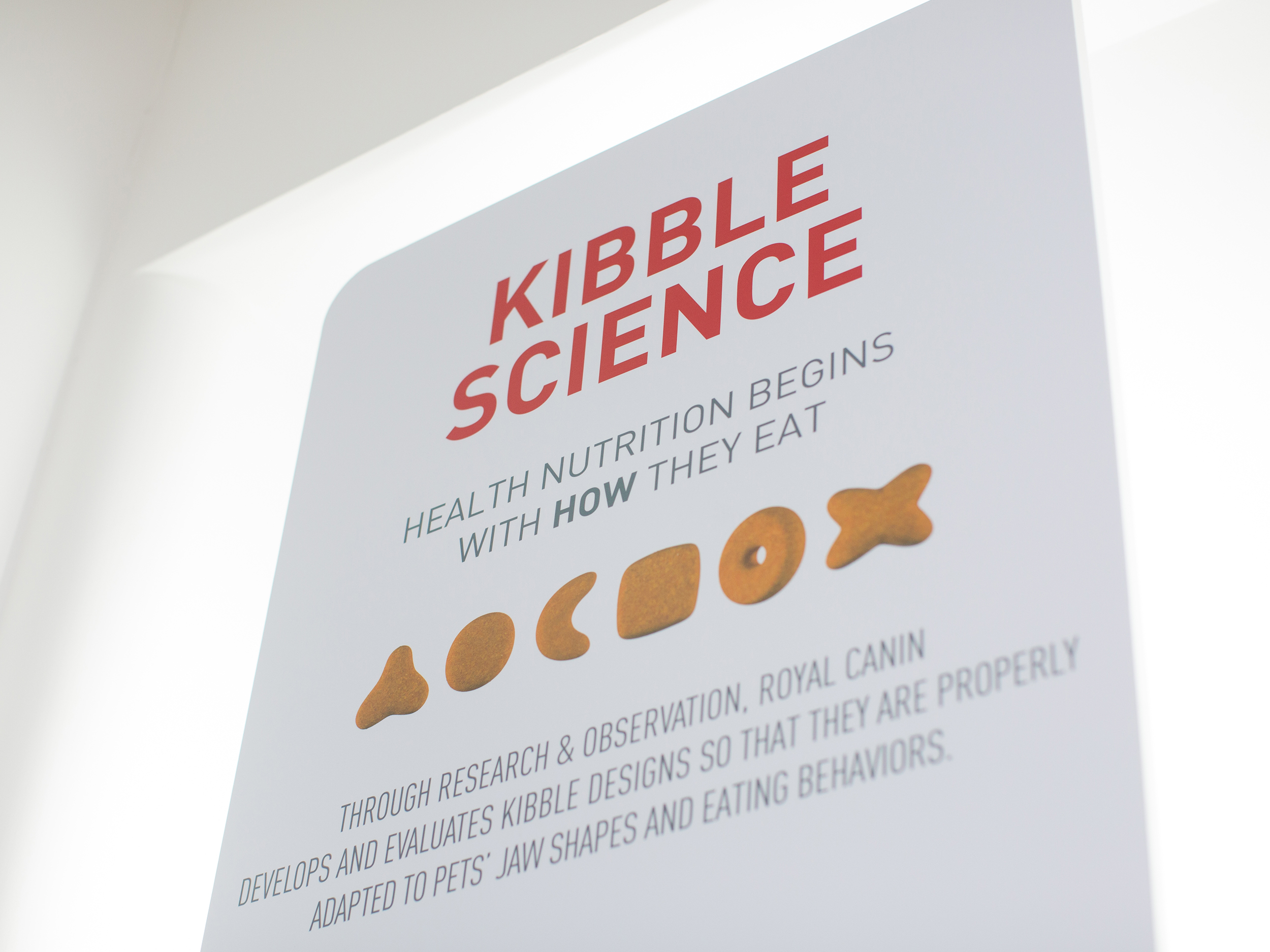

Kibbles of various shapes that differ dependingon the breed of cat and dog

Based on research and observation, Royal Canin has designed tailored kibbles that will fit the shape of the mouth and physiological structure of diverse dog and cat breeds, to facilitate chewing and eating. In addition, the smell, texture and flavor of food, physical friction effect through chewing, high density for satiety, and specific nutrients for optimal digestion are all taken into consideration when devising the best formula with high palatability and digestibility to meet the needs of all types of cats and dogs.

Responsible for quality and safety from raw materialprocurement to product delivery

To pursue quality and food safety of the highest standards, Royal Canin continues to closely monitor the overall manufacturing process of our products. From rigorous raw ingredient inspection all the way to product shipment, we enforce rigid safety and quality standards at each step of production.

Raw materials purchased from the strictly selectedsuppliers all over the world

To guarantee quality and food safety, the utilization of safe, high-quality and strict compliance of raw material selection is our priority. For this reason, we are unrelenting in our screening of suppliers of raw materials. Quality verifications are carried out using near-infrared spectrophotometer data bank based on Royal Canin’s globally common standards. The raw materials are only selected after complying with more than a hundred analyses and inspections on multiple product sample. After that, in-depth auditing aiming at raw material suppliers is then performed to ensure proper control of physical and chemical risks. Furthermore, we make sure that all cooperative suppliers comply with the requirements of Royal Canin in terms of ethical and environmentally-friendly standards. It is only through passing the strict examination processes can the companies and their raw materials become cooperative suppliers of Royal Canin. The approved suppliers can therefore purchase the strictly-selected materials from countries around the world before providing them to our factories.

Each raw material receives multiple inspections

Raw materials in poor condition means nothing despite strict selection. All raw materials are required to go through precise visual and odor inspection processes when they are shipped to the warehouse. To carry out detailed analyses, kilograms of sample materials are collected and sent to testing laboratories for examinations. The content of analysis includes physical factors and nutritional quality test, freshness test for animal protein, mycotoxin test for grains and melamine test for protein. Moreover, it is required that all raw materials receive near-infrared spectrophotometer scan to confirm they meet the standards of our global data base. Raw materials whose spectrogram fails to tally with the specifications will not be accepted. It is only by passing through rigorous inspection process can the raw materials be admitted by the factory.

Manufacturing processes that enable world-widehigh quality and safety standards

No matter by which factory of Royal Canin the products are manufactured, the products are expected to meet our precise globally common quality and safety standards. The quality of all products is controlled through strict standards during the process, and inspections on the finished products are conducted before they are dispatched from the factory.

Precisely measure the raw materials to achievehighly accurate nutritional composition

Royal Canin is known for providing “an exact nutritional balance”. Accurate weight of each raw material is important to create a diet with a highly accurate nutritional composition. This is very important, as minute discrepancies (excess as well as deficiency) in nutrition can endanger the health of cats and dogs.

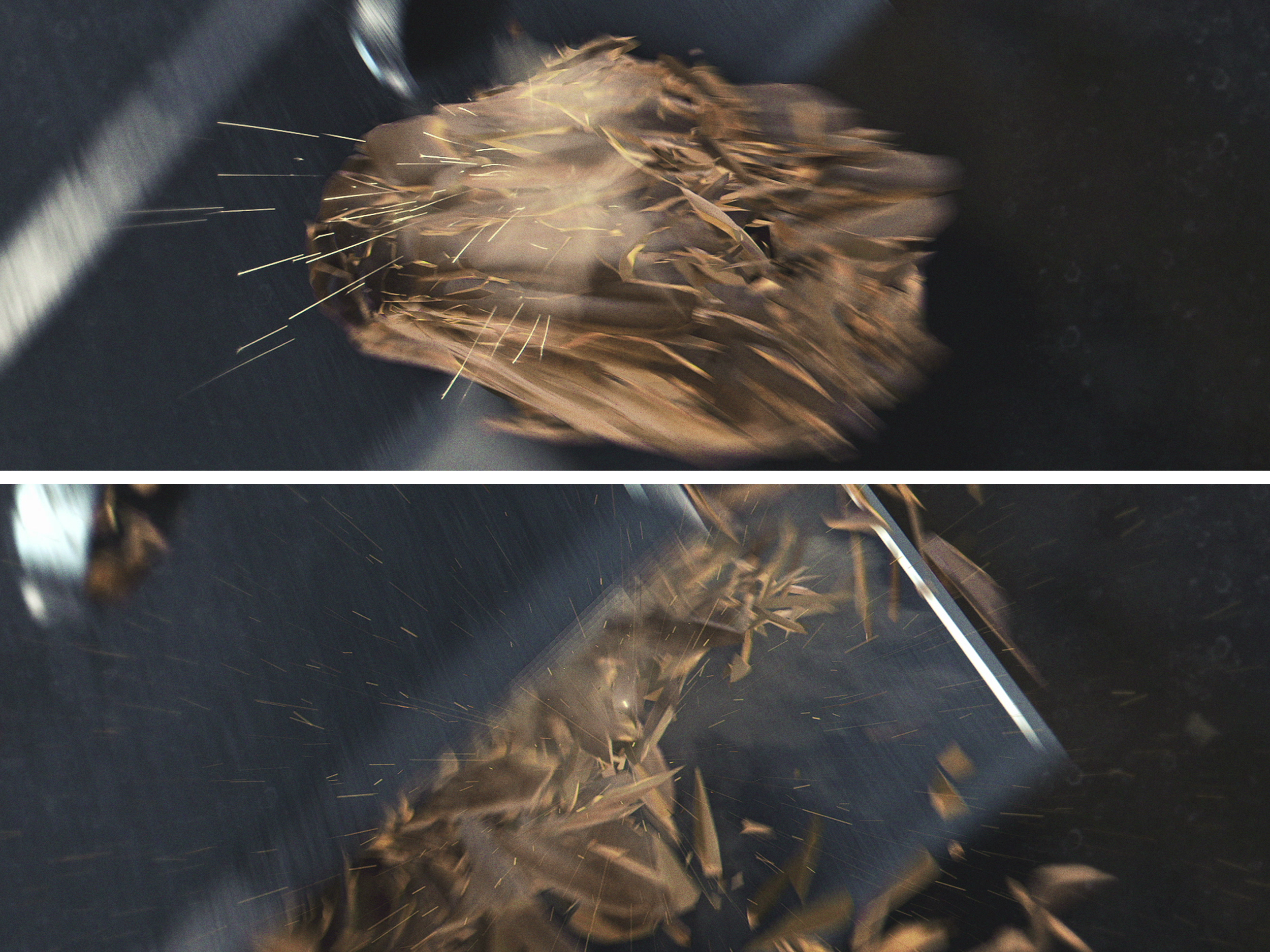

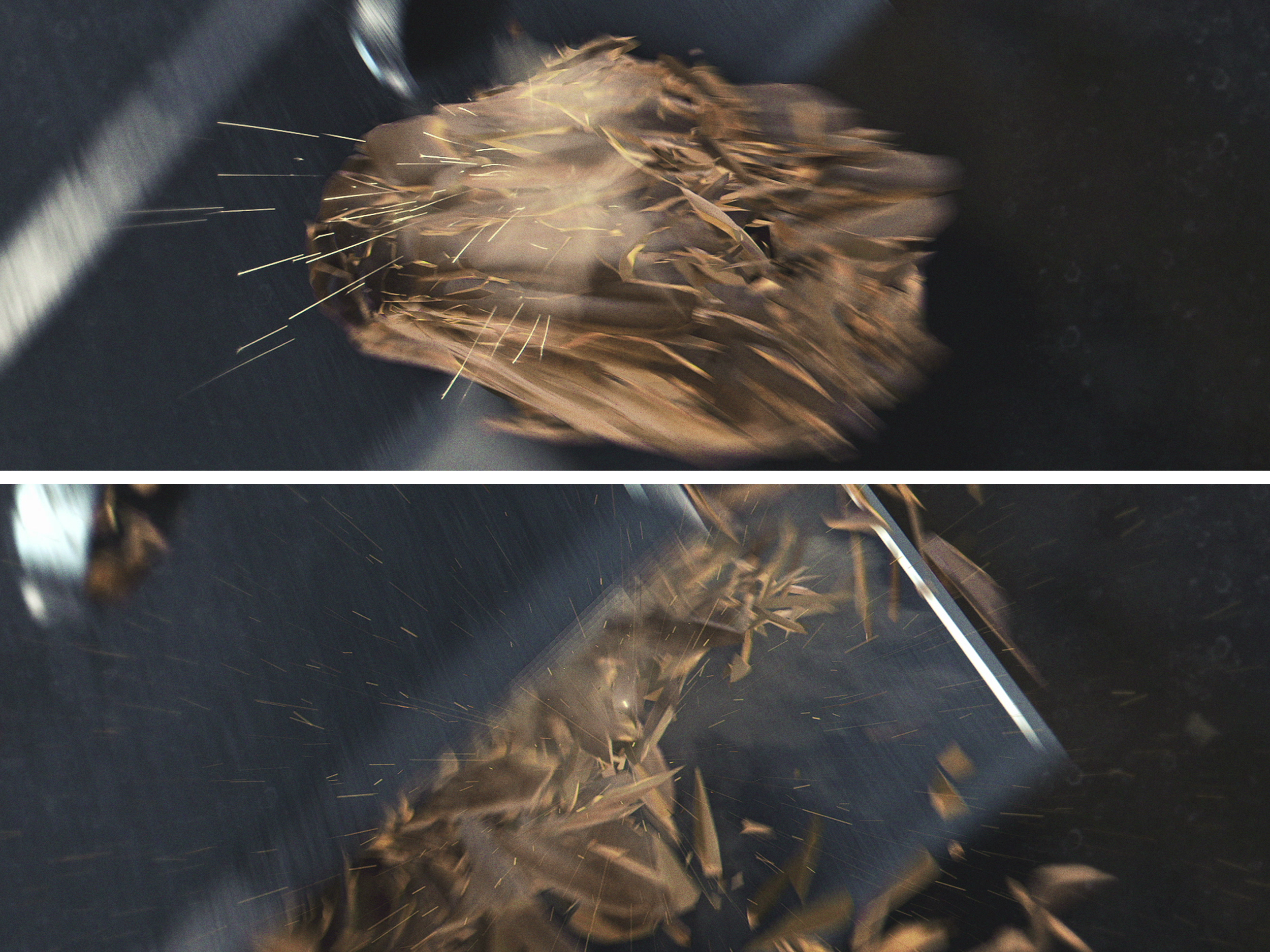

Grind the raw materials into small particles toimprove digestibility and palatability

The precisely measured raw materials are ground into a fine powder. Fine particle size enhances the palatability and digestibility of the final product.

Extrusion molding that cooks under precisetemperature control

Raw materials crushed to a fine particle size are transferred to an extruder. Here, the raw materials are molded into kibbles. The inside of the extruder remains very hot. It is important that the temperature is properly controlled so that the product is sufficiently cooked and the conditions of food safety and quality are satisfied.

Therefore, it is required that the operator conducts constant monitoring to make sure that all parameters meet the prescribed standards. In addition, the sample of the kibbles will be collected at regular intervals to confirm and record physical and chemical aspects. Here, a well-trained operator checks the color, shape, size, density, moisture, protein, and fat content of the kibble using specialized equipment.

Coated with flavors that give the best taste andattraction

The extruded kibble is then sprayed with nutrients after cooling and drying to provide the best palatability for cats and dogs. The coating originates directly from natural animal protein, and a unique spray coating technology is used to ensure the full absorption of flavor. The commitment to palatability is managed on a global level, helping Royal Canin achieve palatability consistency regardless of the location of production.

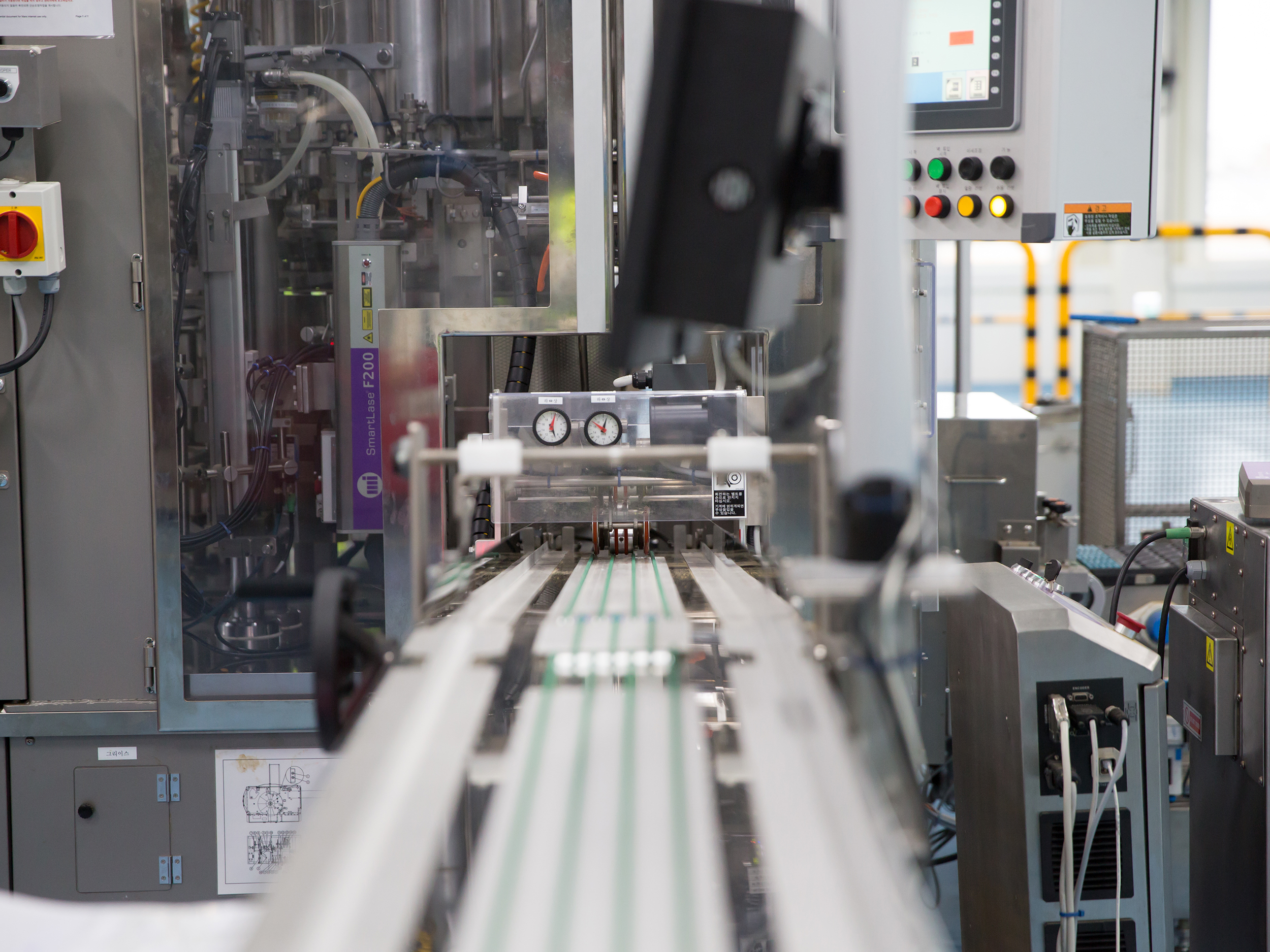

Product packaging keeps the freshness at an optimallevel

To avoid oxidization after production, nitrogen gas packing is adopted by Royal Canin. Nitrogen is filled into the package to dissociate oxygen, and thus the freshness of the product is kept at an optimal level until the expiration date. During this final packaging process, metal detection is also carried out. Final testing is carried out, making sure that the weight of product, seal quality, printing and oxygen residue are within the scope of our global standard.

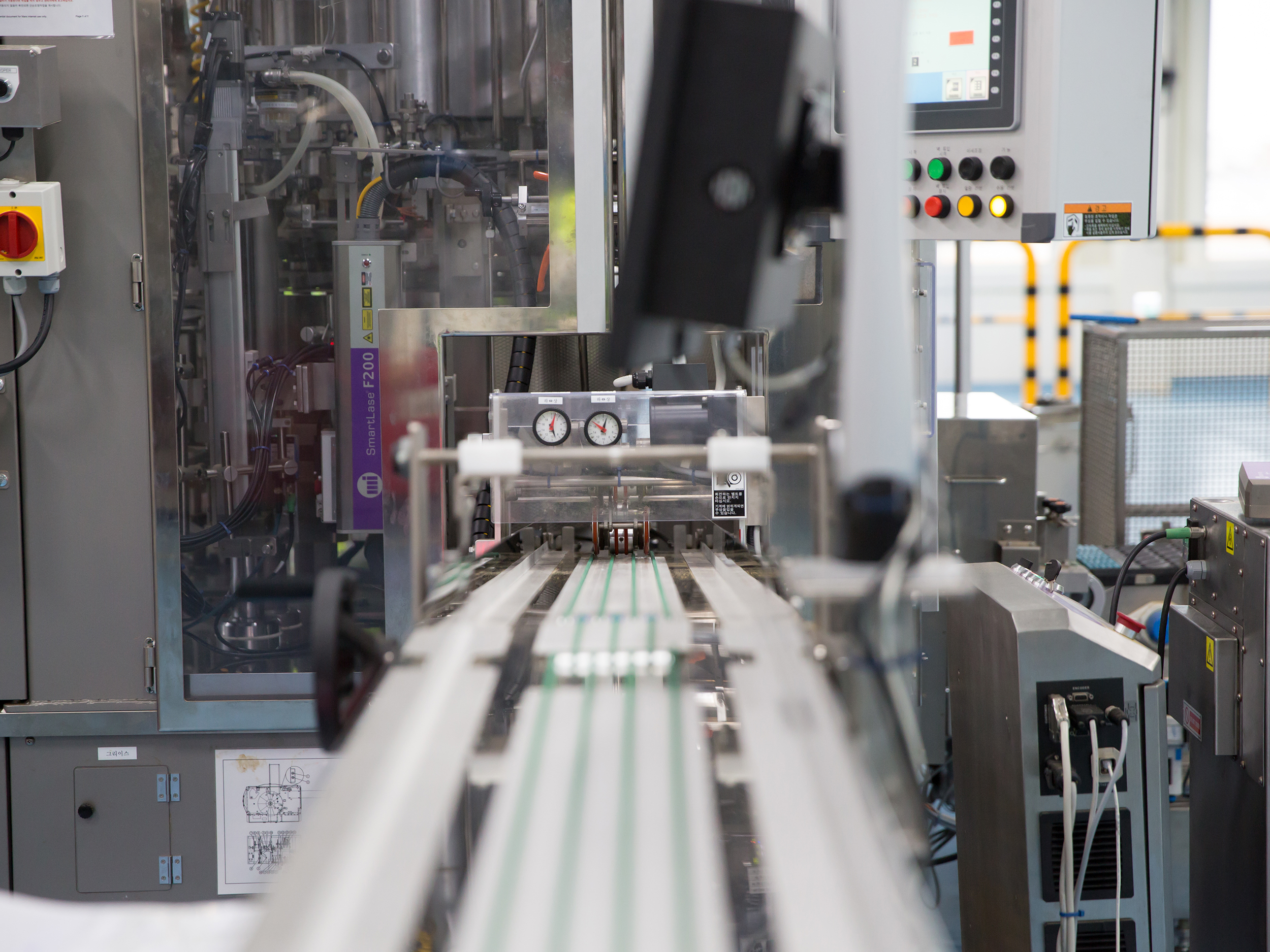

Factory which possesses state-of-the-art equipment

Royal Canin Korean factory is the newest factory built based on the expertise and knowledge of Royal Canin factories worldwide. Led by an operation team with extensive experience in quality control and manufacturing plus the incorporation of the latest equipment, Royal Canin Korean factory expects to provide top-quality products to customers around the world.

The most advanced technology and equipment

The Korean factory was established in 2018 as the 16th global factory of Royal Canin. We have installed the most advanced technology and equipment in the industry. The Korean factory is equipped with state-of-the-art purification column technology which reliably removes foreign substances from all raw materials. In addition, we have introduced the most advanced grinding technology that can improve digestibility and palatability.

In addition, we have adopted the latest technology in packing systems that does not use belts or chain conveyors to prevent the mixing of different products. Products manufactured by Korean factory are like all others produced by other Royal Canin factories (including the French factory). The products are manufactured and shipped out in compliance with the global quality and food safety specifications at the highest level, only after strict quality validation conducted by the headquarters in France.

An area dedicated to the History and Philosophy of Royal Canin

An area which introduces the brand of Royal Canin is set up at the entrance of the factory. The videos and photographs displayed in this area illustrate the history, philosophy, research, development, initiatives, rigorous management of quality and safe and maps of all Royal Canin factories from around the world.

Seminar room dedicated to deepening understanding our quality principles

Before touring the factory, we will introduce the process flow of manufacturing to our guests in the meeting room. Here you can see exhibits about kibble science as well as actual product samples. In this session, it will be fully explained how our commitment to kibble shape and density has a positive effect on palatability, dental health, satiety, digestion, and chewing.

Established a glass-sided corridor to show the manufacturing process to visitors

While observing the actual manufacturing process behind a glass window, visitors can read the introduction of workflow on the corridor wall. Royal Canin Korean factory is the first factory where this kind of safe observation has been incorporated into the factory design. Through the transparency of actual manufacturing condition, customers can purchase and use our products with more confidence.

Obtained global certification “LEED Gold Certificate”for dedication to energy saving and the environment

LEED (Leadership in Energy and Environmental Design) is an environmental performance evaluation system for buildings and site use that is developed and applied by USGBC: US Green Building Council (NPO). In recognition of excellent performance on energy conservation and environmental protection, Royal Canin Korean factory is the first Royal Canin factory obtaining the “LEED Gold Certificate”. In the aspect of energy saving, water conservation and control of waste discharge, the performance reflects the ingenious design concept of Korean factory. The accomplishment of zero landfill has already been fulfilled during the early stage of establishment.

Interview Factory equipped with the latest technology and facilities

The passion of each employee who works to enable “true health” for all cats and dogs are infused into Royal Canin’s products. This Korean factory is operated and managed by an elite multi-national team, formed by associates with experience in manufacturing and quality control gained from other Royal Canin factories around the world (for example, France, Poland, Japan, etc.). The operation team at the Korean factory has been trained to become skillful at all processes related to product manufacturing, from product quality control and food safety, to continuous improvement of raw materials selection to reflect customer feedback and comments. Moreover, all employees are required to receive on-the-job training for several months at the Royal Canin factory in France.

Our Message

We at Royal Canin continue to develop nutrition that brings true health to every dog and cat, based on our philosophy "Dogs and Cats First". No matter where the products are manufactured, all factories of Royal Canin around the world are required to abide by globally uniform standards for quality and food safety to produce pet food products of the highest quality.

Royal Canin Pet Food

All products of Royal Canin are developed by the world-leading team of dietitian nutritionists at the headquarters in France. No matter where the products are manufactured, the quality and characteristic of the product conforms to our global standards. Product development includes long-term observations on cats and dogs raised by the pet centers located in Aimargues, France and Lewisburg, State of Ohio, U.S.A., together with the study on the uniqueness of different cat and dog breeds.

Optimal nutritional balance to protect pet’shealth

The nutritional demand of cats and dogs varies according to breed, age, body type and lifestyle. Royal Canin has developed pet foods suitable for different types of cat and dog by integrating more than 40 kinds of nutrients in accordance with the principle of nutritional balance. Moreover, pet foods that can satisfy special needs are also developed: cats and dogs with certain diseases or at older ages, for instance.

Kibbles of various shapes that differ dependingon the breed of cat and dog

Based on research and observation, Royal Canin has designed tailored kibbles that will fit the shape of the mouth and physiological structure of diverse dog and cat breeds, to facilitate chewing and eating. In addition, the smell, texture and flavor of food, physical friction effect through chewing, high density for satiety, and specific nutrients for optimal digestion are all taken into consideration when devising the best formula with high palatability and digestibility to meet the needs of all types of cats and dogs.

Responsible for quality and safety from raw materialprocurement to product delivery

To pursue quality and food safety of the highest standards, Royal Canin continues to closely monitor the overall manufacturing process of our products. From rigorous raw ingredient inspection all the way to product shipment, we enforce rigid safety and quality standards at each step of production.

Raw materials purchased from the strictly selectedsuppliers all over the world

To guarantee quality and food safety, the utilization of safe, high-quality and strict compliance of raw material selection is our priority. For this reason, we are unrelenting in our screening of suppliers of raw materials. Quality verifications are carried out using near-infrared spectrophotometer data bank based on Royal Canin’s globally common standards. The raw materials are only selected after complying with more than a hundred analyses and inspections on multiple product sample. After that, in-depth auditing aiming at raw material suppliers is then performed to ensure proper control of physical and chemical risks. Furthermore, we make sure that all cooperative suppliers comply with the requirements of Royal Canin in terms of ethical and environmentally-friendly standards. It is only through passing the strict examination processes can the companies and their raw materials become cooperative suppliers of Royal Canin. The approved suppliers can therefore purchase the strictly-selected materials from countries around the world before providing them to our factories.

Each raw material receives multiple inspections

Raw materials in poor condition means nothing despite strict selection. All raw materials are required to go through precise visual and odor inspection processes when they are shipped to the warehouse. To carry out detailed analyses, kilograms of sample materials are collected and sent to testing laboratories for examinations. The content of analysis includes physical factors and nutritional quality test, freshness test for animal protein, mycotoxin test for grains and melamine test for protein. Moreover, it is required that all raw materials receive near-infrared spectrophotometer scan to confirm they meet the standards of our global data base. Raw materials whose spectrogram fails to tally with the specifications will not be accepted. It is only by passing through rigorous inspection process can the raw materials be admitted by the factory.

Manufacturing processes that enable world-widehigh quality and safety standards

No matter by which factory of Royal Canin the products are manufactured, the products are expected to meet our precise globally common quality and safety standards. The quality of all products is controlled through strict standards during the process, and inspections on the finished products are conducted before they are dispatched from the factory.

Precisely measure the raw materials to achievehighly accurate nutritional composition

Royal Canin is known for providing “an exact nutritional balance”. Accurate weight of each raw material is important to create a diet with a highly accurate nutritional composition. This is very important, as minute discrepancies (excess as well as deficiency) in nutrition can endanger the health of cats and dogs.

Grind the raw materials into small particles toimprove digestibility and palatability

The precisely measured raw materials are ground into a fine powder. Fine particle size enhances the palatability and digestibility of the final product.

Extrusion molding that cooks under precisetemperature control

Raw materials crushed to a fine particle size are transferred to an extruder. Here, the raw materials are molded into kibbles. The inside of the extruder remains very hot. It is important that the temperature is properly controlled so that the product is sufficiently cooked and the conditions of food safety and quality are satisfied.

Therefore, it is required that the operator conducts constant monitoring to make sure that all parameters meet the prescribed standards. In addition, the sample of the kibbles will be collected at regular intervals to confirm and record physical and chemical aspects. Here, a well-trained operator checks the color, shape, size, density, moisture, protein, and fat content of the kibble using specialized equipment.

Coated with flavors that give the best taste andattraction

The extruded kibble is then sprayed with nutrients after cooling and drying to provide the best palatability for cats and dogs. The coating originates directly from natural animal protein, and a unique spray coating technology is used to ensure the full absorption of flavor. The commitment to palatability is managed on a global level, helping Royal Canin achieve palatability consistency regardless of the location of production.

Product packaging keeps the freshness at an optimallevel

To avoid oxidization after production, nitrogen gas packing is adopted by Royal Canin. Nitrogen is filled into the package to dissociate oxygen, and thus the freshness of the product is kept at an optimal level until the expiration date. During this final packaging process, metal detection is also carried out. Final testing is carried out, making sure that the weight of product, seal quality, printing and oxygen residue are within the scope of our global standard.

Factory which possesses state-of-the-art equipment

Royal Canin Korean factory is the newest factory built based on the expertise and knowledge of Royal Canin factories worldwide. Led by an operation team with extensive experience in quality control and manufacturing plus the incorporation of the latest equipment, Royal Canin Korean factory expects to provide top-quality products to customers around the world.

The most advanced technology and equipment

The Korean factory was established in 2018 as the 16th global factory of Royal Canin. We have installed the most advanced technology and equipment in the industry. The Korean factory is equipped with state-of-the-art purification column technology which reliably removes foreign substances from all raw materials. In addition, we have introduced the most advanced grinding technology that can improve digestibility and palatability.

In addition, we have adopted the latest technology in packing systems that does not use belts or chain conveyors to prevent the mixing of different products. Products manufactured by Korean factory are like all others produced by other Royal Canin factories (including the French factory). The products are manufactured and shipped out in compliance with the global quality and food safety specifications at the highest level, only after strict quality validation conducted by the headquarters in France.

An area dedicated to the History and Philosophy of Royal Canin

An area which introduces the brand of Royal Canin is set up at the entrance of the factory. The videos and photographs displayed in this area illustrate the history, philosophy, research, development, initiatives, rigorous management of quality and safe and maps of all Royal Canin factories from around the world.

Seminar room dedicated to deepening understanding our quality principles

Before touring the factory, we will introduce the process flow of manufacturing to our guests in the meeting room. Here you can see exhibits about kibble science as well as actual product samples. In this session, it will be fully explained how our commitment to kibble shape and density has a positive effect on palatability, dental health, satiety, digestion, and chewing.

Established a glass-sided corridor to show the manufacturing process to visitors

While observing the actual manufacturing process behind a glass window, visitors can read the introduction of workflow on the corridor wall. Royal Canin Korean factory is the first factory where this kind of safe observation has been incorporated into the factory design. Through the transparency of actual manufacturing condition, customers can purchase and use our products with more confidence.

Obtained global certification “LEED Gold Certificate”for dedication to energy saving and the environment

LEED (Leadership in Energy and Environmental Design) is an environmental performance evaluation system for buildings and site use that is developed and applied by USGBC: US Green Building Council (NPO). In recognition of excellent performance on energy conservation and environmental protection, Royal Canin Korean factory is the first Royal Canin factory obtaining the “LEED Gold Certificate”. In the aspect of energy saving, water conservation and control of waste discharge, the performance reflects the ingenious design concept of Korean factory. The accomplishment of zero landfill has already been fulfilled during the early stage of establishment.

Interview Factory equipped with the latest technology and facilities

The passion of each employee who works to enable “true health” for all cats and dogs are infused into Royal Canin’s products. This Korean factory is operated and managed by an elite multi-national team, formed by associates with experience in manufacturing and quality control gained from other Royal Canin factories around the world (for example, France, Poland, Japan, etc.). The operation team at the Korean factory has been trained to become skillful at all processes related to product manufacturing, from product quality control and food safety, to continuous improvement of raw materials selection to reflect customer feedback and comments. Moreover, all employees are required to receive on-the-job training for several months at the Royal Canin factory in France.

Our Message

We at Royal Canin continue to develop nutrition that brings true health to every dog and cat, based on our philosophy "Dogs and Cats First". No matter where the products are manufactured, all factories of Royal Canin around the world are required to abide by globally uniform standards for quality and food safety to produce pet food products of the highest quality.

For a sustainable future

Sustainability is central to every aspect of Royal Canin’s daily global operations.